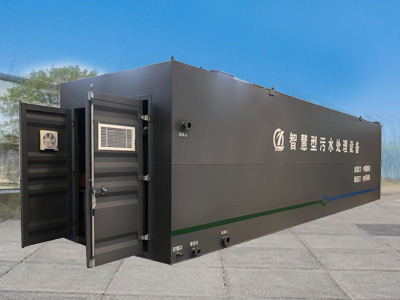

一体化污水处理设备Integrated sewage treatment equipm

编辑:出口污水处理设备 来自:https://www.zqwscl.com / 日期:2022-03-17 10:18 / 人气:

Integrated sewage treatment equipment

WSZ Series Integrated Sewage Treatment Equipment

Patent No.: ZL 2015 2 1138799.7

I. Overview

With the growth of economy and population, more and more attention has been paid to the pollution of nature. On the basis of summarizing the operating experience of domestic and foreign domestic sewage treatment facilities and combining with our own scientific research achievements and engineering practice, we have designed a complete set of buried organic wastewater treatment equipment. This equipment adopts advanced technology and manufacturing technology in China and abroad, and produces the sewage treatment equipment with glass fiber, carbon steel and non-steel as the main material. Its main purpose is to make domestic sewage and similar industrial organic wastewater meet the discharge standard required by users after being treated by the equipment.

The equipment is mainly used for domestic sewage treatment in residential districts (including villas), high standard hotels, hospitals, comprehensive office buildings and various public buildings. The effluent quality treated by the equipment meets the national discharge standard. The whole set of equipment can be buried underground, so it is also called "geographical domestic sewage treatment equipment".

The company's buried domestic sewage treatment equipment adopts international advanced biological treatment technology, integrates removal of BOD5, COD and NH3-N, with the advantages of stable and reliable technical performance, good treatment effect, less investment, less land occupation and convenient maintenance, etc. Our company can also provide reclaimed water reuse equipment according to requirements of customers.

II. Structure and Principle

III. Application Method of Integrated Sewage Treatment Equipment

1. It is able to treat integrated comprehensive wastewater of living system and the similar organic wastewater;

2. The complete set of equipment is simple in construction and easy to operate. All mechanical equipment is automatically controlled, and all the equipment can be set below the surface of the earth;

3. It is easy to manage and maintain. The equipment is equipped with automatic control system;

Ⅳ. Scope of Application

1. Hotels, restaurants, sanitariums and hospitals;

2. Residential districts, villages and markets and towns;

3. Stations, airports, harbor, wharves and ships;

4. Plants, mines, troops, tourist spots and scenic areas;

5. Various industrial organic waste water similar to domestic sewage;

V. Process Flow

VI. Product Characteristics

1. It is buried below the surface of the ground. The surface above the equipment can be used as greening or other land, and there is no need to build houses, heating and insulation.

2. The push flow biological contact oxidation is adopted in the process of bio-contact oxidation, and its treatment effect is better than that of fully mixed or secondary series connection fully mixed bio-contact oxidation tank. The well is smaller than the activated sludge pond, has stronger adaptability to water quality, good shock load resistance, stable effluent water quality and no sludge bulking. In the tank, a novel composite filler is used, which has large specific surface area, and the microorganism is easy to hang membrane and membrane removal. Under the same organic loading conditions, the removal rate of organic matter is high, so that the solubility of oxygen in the air can be improved in water.

3. The biochemical pond adopts bio-contact oxidation method, the volume load of its filler is low, the microorganism is in self-oxidation step, the production of mud is little, only three months (90 days) and more than one discharge of mud (suction with dung cart or dehydration into mud cake).

4. The deodorization mode of the buried sewage treatment equipment not only adopts the conventional high altitude exhaust, and is also equipped with the soil deodorization measure.

5. The whole equipment processing system is equipped with full automatic electric control system and equipment fault alarm system. It is safe and reliable to operate. Usually, it doesn't need a specially designated person for management, and only needs timely overhaul and maintenance of the equipment.

VII. Performance parameters

1. It is buried below the surface of the ground. The surface above the equipment can be used as greening or other land, and there is no need to build houses, heating and insulation.

2. The push flow biological contact oxidation is adopted in the process of bio-contact oxidation, and its treatment effect is better than that of fully mixed or secondary series connection fully mixed bio-contact oxidation tank. The well is smaller than the activated sludge pond, has stronger adaptability to water quality, good shock load resistance, stable effluent water quality and no sludge bulking. In the tank, a novel composite filler is used, which has large specific surface area, and the microorganism is easy to hang membrane and membrane removal. Under the same organic loading conditions, the removal rate of organic matter is high, so that the solubility of oxygen in the air can be improved in water.

3. The biochemical pond adopts bio-contact oxidation method, the volume load of its filler is low, the microorganism is in self-oxidation step, the production of mud is little, only three months (90 days) and more than one discharge of mud (suction with dung cart or dehydration into mud cake).

4. The deodorization mode of the buried sewage treatment equipment not only adopts the conventional high altitude exhaust, and is also equipped with the soil deodorization measure.

5. The whole equipment processing system is equipped with full automatic electric control system and equipment fault alarm system. It is safe and reliable to operate. Usually, it doesn't need a specially designated person for management, and only needs timely overhaul and maintenance of the equipment.

VII. Performance parameters

VIII. Product Advantages

• With high degree of automation, it can achieve unattended and remote monitoring;

• Each equipment has passed the strict ex-factory inspection, with low failure rate and maintenance free;

• Each equipment is equipped with two systems including mixed liquid reflux and sludge reflux, the backflow can be adjusted according to the change of water quality, denitrification can be achieved by reflux denitrification of the mixture, and the number of bacteria is ensured by sludge return, and the operation is stable;

• The shell is made of carbon steel, stainless steel or glass fiber reinforced plastic. The carbon steel is made of epoxy coal tar paint for antisepsis.

• The inner part of the equipment is provided with stiffener, the buried depth can reach more than 2 m, and it can also be used on the ground;

• Each bin of the equipment is equipped with a water distribution system. There is no short circuit in the water flow. The utilization rate of the tank can reach 89.8%, 15%-30% more than that of the non-water distribution system or the conventional water distribution system;

• The special micro-pore aeration device without clogging can make the sewage mixed fully with activated sludge and dissolved oxygen, which can greatly improve the oxygen transfer efficiency and the biochemical activity of sludge;

• The equipment is filled with functional biological affinity composite filler, which has the advantages of rapid film formation, rapid microbial growth and high activity, so the effluent quality is good.

IX. Model Meaning

WSZ—AO/M/T—A/F/S—

WSZ—AO/M/T—A/F/S—

WSZ—integrated sewage treatment equipment

AO— —AO Process M—MBR Process T—Solar A——Steel plate module

F—FRP (FRP module) S—Stainless steel ——Processing capacity

F—FRP (FRP module) S—Stainless steel ——Processing capacity

X. Technical Parameter List of WSZ-A

• With high degree of automation, it can achieve unattended and remote monitoring;

• Each equipment has passed the strict ex-factory inspection, with low failure rate and maintenance free;

• Each equipment is equipped with two systems including mixed liquid reflux and sludge reflux, the backflow can be adjusted according to the change of water quality, denitrification can be achieved by reflux denitrification of the mixture, and the number of bacteria is ensured by sludge return, and the operation is stable;

• The shell is made of carbon steel, stainless steel or glass fiber reinforced plastic. The carbon steel is made of epoxy coal tar paint for antisepsis.

• The inner part of the equipment is provided with stiffener, the buried depth can reach more than 2 m, and it can also be used on the ground;

• Each bin of the equipment is equipped with a water distribution system. There is no short circuit in the water flow. The utilization rate of the tank can reach 89.8%, 15%-30% more than that of the non-water distribution system or the conventional water distribution system;

• The special micro-pore aeration device without clogging can make the sewage mixed fully with activated sludge and dissolved oxygen, which can greatly improve the oxygen transfer efficiency and the biochemical activity of sludge;

• The equipment is filled with functional biological affinity composite filler, which has the advantages of rapid film formation, rapid microbial growth and high activity, so the effluent quality is good.

IX. Model Meaning

WSZ—integrated sewage treatment equipment

AO— —AO Process M—MBR Process T—Solar A——Steel plate module

X. Technical Parameter List of WSZ-A